What we do

Evtec Aluminium supplies lightweight aluminium castings to major automotive manufacturers around the world. We provide a strategically crucial link in the supply chain as lightweighting is critical as the industry transitions to Net Zero.

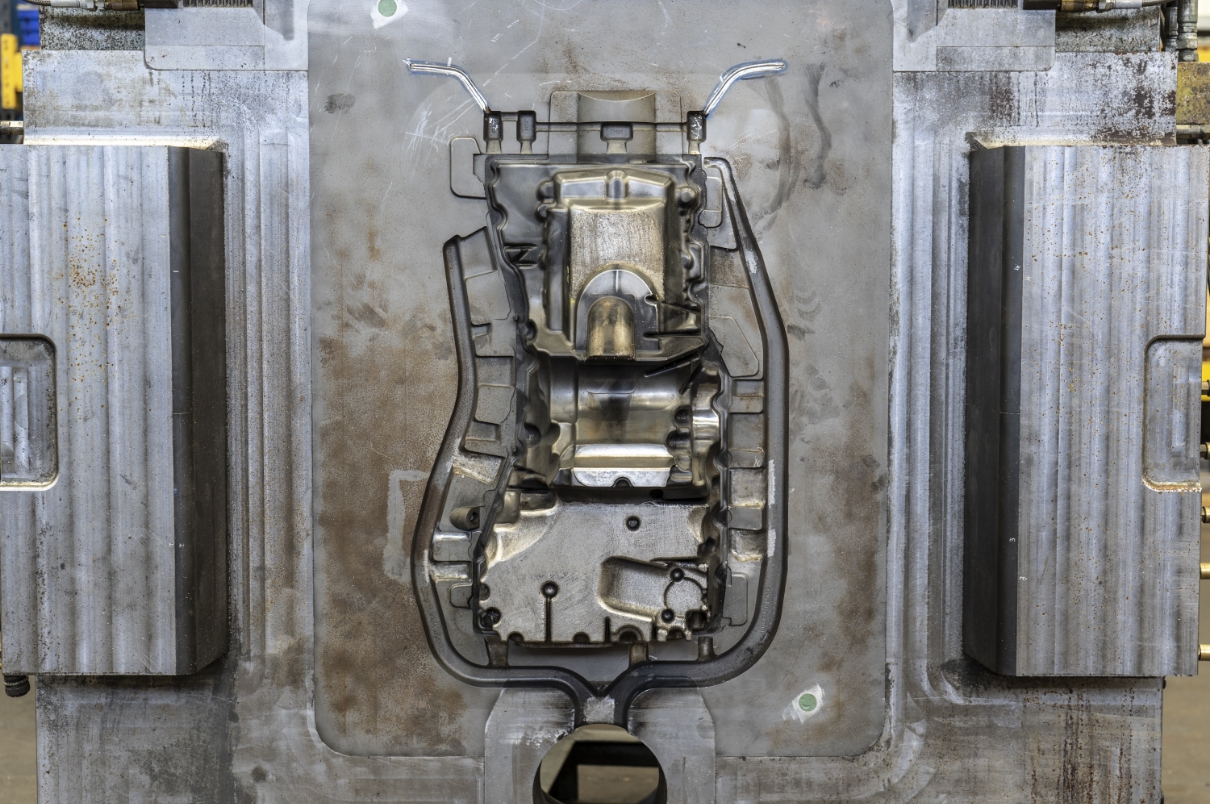

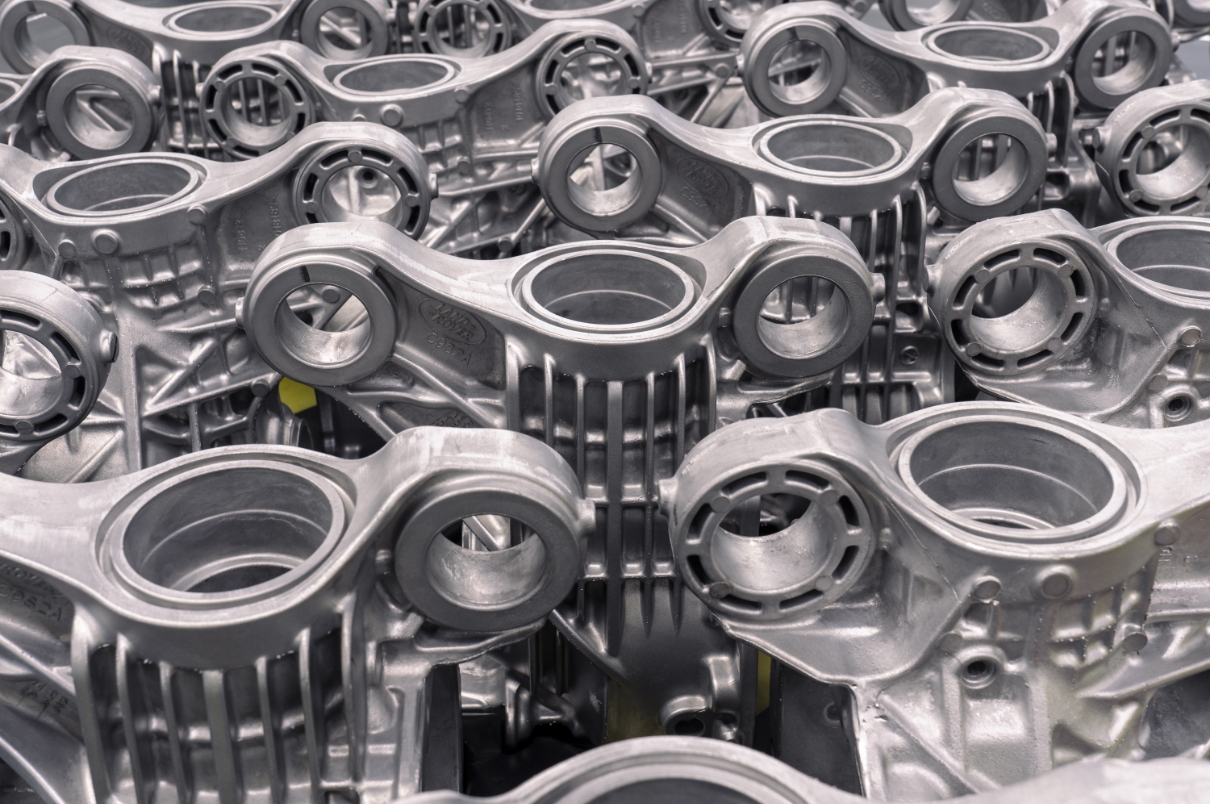

High-pressure die casting is a process whereby molten aluminium is injected, under pressure, into a sealed mould cavity known as a “die”. It is held in place by powerful hydraulics until the metal cools and solidifies. Following solidification, the die is released, opened and the cast metal is removed. This process enables Evtec Aluminium to produce large volumes of components, perfect every time with just 2% wastage.

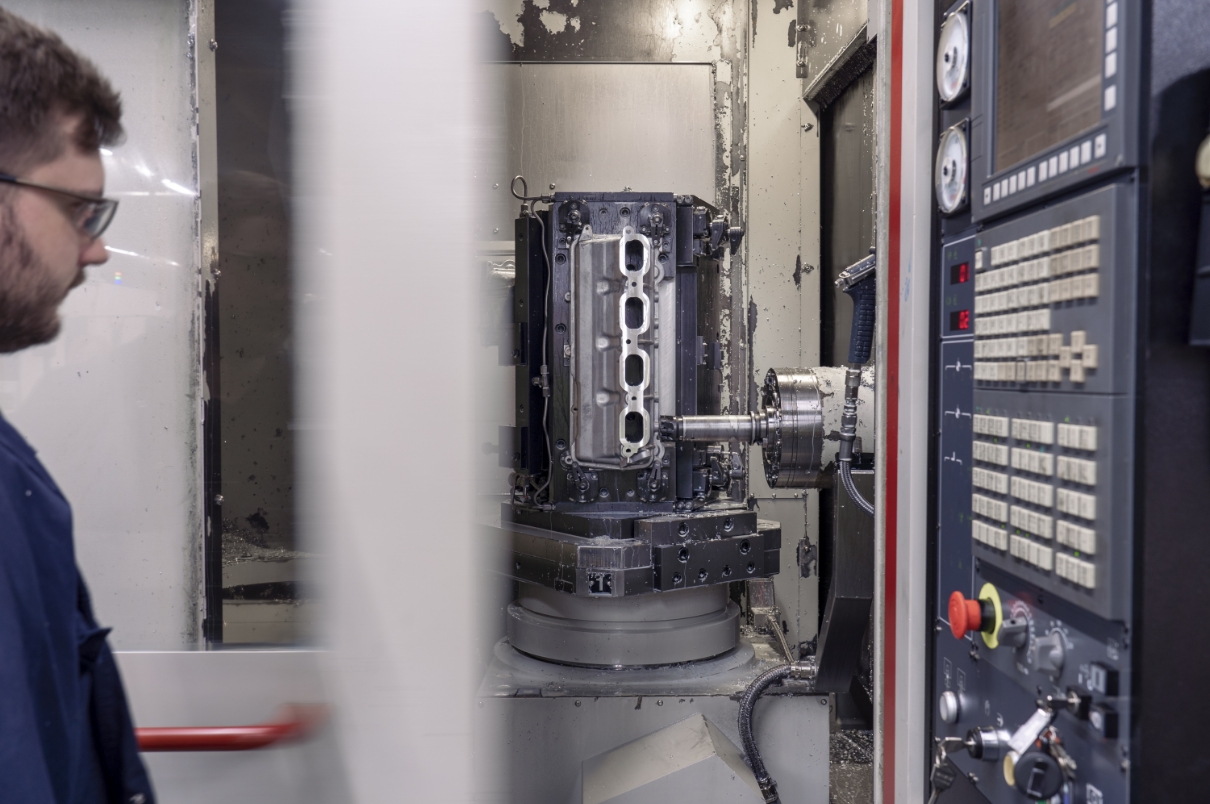

CNC Machining is a computerised manufacturing process in which software controls the exact movement of milling equipment. Our CNC machine tools range from three to full five axis movement enabling us to produce the most complex and intricate components from a range of materials giving us the flexibility from prototype to high volume production.

Many of our customers ask for their components to come pre-assembled to ensure they’re ready to fit on the production line. This is something we can factor into the product and we’re able to do any assembly required.

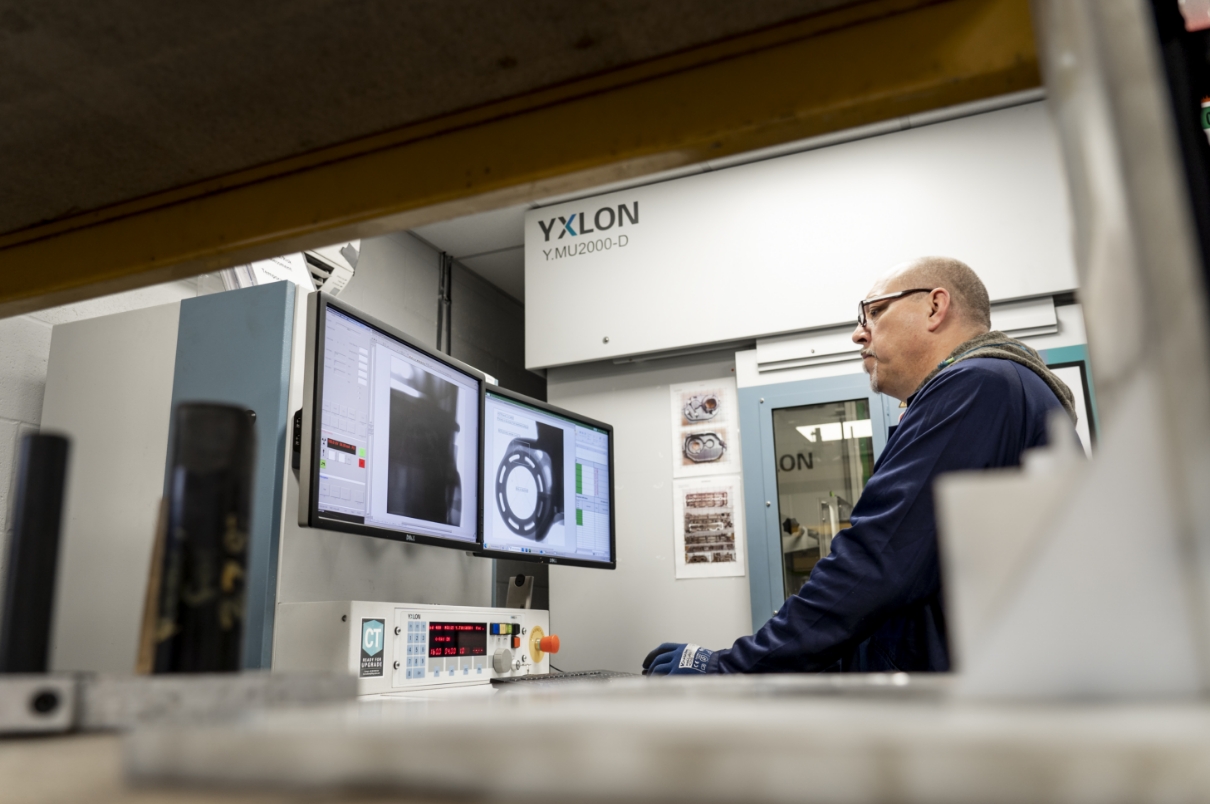

Here at Evtec Aluminium we conduct a range of tests including; visual inspections, X-ray and coordinate measuring machine (CMM) – laser measuring the geometry to ensure every component is designed to the exacting tolerances set by our customers.

strong supplier network

Up to 5,000 components

created every day

Operating 24/7 across 3 shifts

Design for Manufacturing is the optimisation of a part, product or component’s design, to create it cheaper and more easily. Our team can optimise your components for maximum efficiencies of products. Reducing waste, material and machine time.

Evtec Aluminium prides itself on providing turnkey solutions for customers. From prototyping and product design to development and manufacturing our team can be your one-stop-shop to provide the complete solution.

“Quality at the centre of everything we do. I work closely with the teams on the shopfloor and the production engineers to ensure every part we make is within tolerances agreed with our customers”